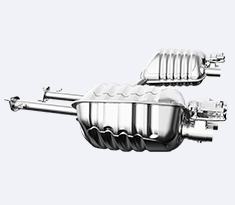

- Exhaust Manifold

- The exhaust manifold serves to collect and discharge hot exhaust gas produced in each cylinder of the engine. Based on our accumulated know-how here at SJG SEJONG we are constantly developing materials for performance enhancement as well as high-quality products with high efficiency. Recently we completed development of and are now supplying an air-gap manifold with superior performance which optimizes engine output and noise reduction compared with existing manifolds, making us the first of Hyundai and Kia motors' partners to do so.

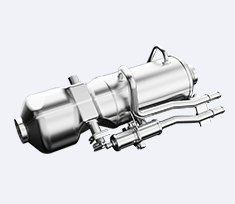

- Catalytic Converter

- The catalytic converter takes some of the toxic gases generated in the combustion process inside the engine, such as hydrocarbons, carbon monoxide and nitrogen oxide, and converts them into non-toxic gases. The catalytic converters for gasoline engines being developed and produced by SJG SEJONG are a warm-up catalytic converter, an under floor catalytic converter and a close coupled catalytic converter. Our products for diesel engines are a diesel oxidation converter which filters hydrogen carbonate, a diesel particulate filter which removes fine soot particles and a selective catalytic reducer which purifies nitrogen oxides. We are supplying these catalytic conversion products to Hyundai and Kia Motors for use in their commercial vehicles.

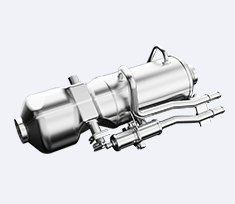

- Selective Catalytic Reduction(SCR)

- This is a nitrogen oxide purification device that we have developed in line with the ever-tightening regulations on exhaust emissions. The selective catalytic reducer induces chemical reactions between nitrogen oxide (NOx) with ammonia (NH3) to transform and release it as harmless water (H2O) and nitrogen (N2). SJG SEJONG has developed and is now producing a selective catalytic reducer diesel engine for passenger and commercial vehicles. We continue to improve our technological competitiveness to satisfy increasingly stringent environmental regulations regarding automobiles.

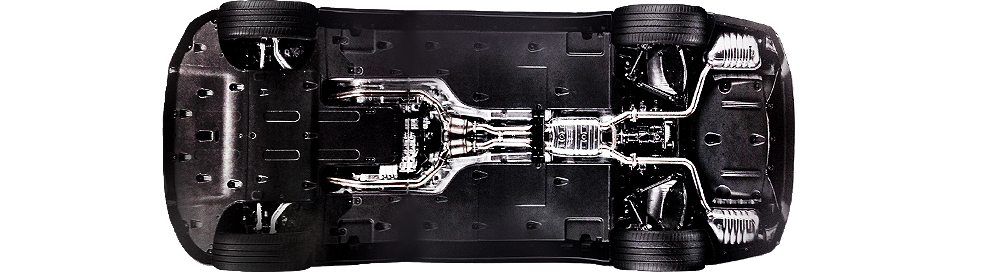

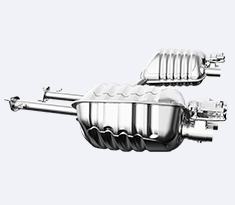

- Sub Resonator

- The sub resonator transforms hot and high pressure

gas into cool and low pressure gas, and is the

primary noise reduction device.

- Main Resonator

- The main resonator has the function of releasing the final exhaust gas into the air and also contributes to noise reduction.

Automobile regulations and environmental protection are becoming the center of focus amid growing global concern over environmental pollution. SJG SEJONG is responding positively to the globally tightening regulations regarding exhaust emissions and is also constantly striving and investing in research for technological advancement in noise pollution reduction, exhaust heat recovery and part weight reduction.

-

Exhaust Gas Reduction Technology

Exhaust Gas Reduction Technology for Gasoline Engines

As diesel cars increase in popularity due to their higher fuel efficiency, the use of GDI (gasoline direct injection) engines is increasing. The GDI engine, which directly injects gasoline into the cylinders, is different from previous engines as it requires a countermeasure for the particle number (PN).

SJG SEJONG is in the process of developing the GPF (gasoline particulate filter), which reduces particulate matter emissions from GDI engines, in response to the ever-increasing emissions regulations. We are focusing on developing technology to minimize noise, vibration and harshness (NVH).

-

Effective Nitrogen Oxide (NOx) Reduction Technology

SJG CENTRAL R&D CENTER is seriously controlling nitrogen oxide emission and is in the process of developing a selective catalytic reduction device with improved performance, packaging and durability in response to the globally tightening automotive industry environmental laws and real driving emissions (RDE) regulations of the European Union. The selective catalytic reduction device is installed in the optimum engine location, and technological development for optimizing fuel efficiency and reducing carbon oxide emissions is being realized through development of insulation technology and a mixer.

-

Energy Recovery: Exhaust Heat Recovery System

Exhaust Heat Recovery System Technology to Improve Fuel Efficiency

This technology has been developed in response to the tightening of fuel efficiency regulations in recent times. It recovers discarded exhaust heat to shorten the amount of time it takes to warm up the car engine, thereby enhancing a power train cooling efficiency. It induces rapid warming up of the engine which prevents energy waste and lowers viscosity of the transmission fluid which improves fuel efficiency and heating performance during the cold season.

-

Noise Reduction Technology

Technology for Noise Reduction with the Semi Active Muffler (SAM) and Improved Engine Performance

The Semi Active Muffler (SAM) uses variable valves which reduce exhaust noise by variably regulating the hydraulic pressure of flowing liquid and gas on the inside and at the end points of tubes which have a frequently changing flow rate. The noise reduction effect is excellent at a low load (low RPM). We are currently focusing on researching and developing a product with improved fuel efficiency and driving performance by reducing weight.

-

Electric Control Exhaust Valve (ECEV) Technology for Reduced Back Pressure, Emissions and Noise Pollution

The Electric Control Exhaust Valve variably regulates exhaust system pressure (differential pressure with air pressure, back pressure) with variable flow rate depending on the operating condition of the vehicle. With our own technology, SJG SEJONG is in the process of developing an electric valve which makes up for the disadvantages of existing variable valves which rely on the flow rate of exhaust gas. We are doing our utmost to develop a highly effective electric valve with improved driving performance and fuel efficiency, and reduced back pressure and noise.

-

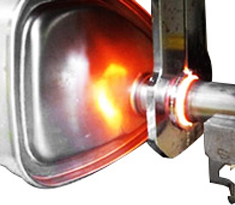

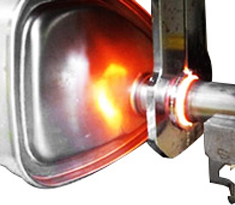

Technology for Lightweight Parts

Technology for Lightweight Parts and High Functionality Applying Induction Brazing

In order for a company to remain competitive in the global automotive market, it requires weight reducing technology to improve fuel efficiency and performance. Induction brazing technology makes high speed warm-up possible using high frequency induced current skin effect. Since the temperature can be easily regulated, it is possible to apply the technology to thinner plates than existing ones which achieves weight reduction.

본 웹사이트에 게시된 이메일주소가 전자우편 수집 프로그램이나

본 웹사이트에 게시된 이메일주소가 전자우편 수집 프로그램이나  본 웹사이트에 게시된 이메일주소가 전자우편 수집 프로그램이나

본 웹사이트에 게시된 이메일주소가 전자우편 수집 프로그램이나  We boast the highest quality products which meet international emission control standards.

We boast the highest quality products which meet international emission control standards.