We have global competitiveness as we take the lead in the production of eco-friendly and

high-efficiency electromechanical part technology.

SJG SEJONG is acquiring core part technology in preparation for full-scale

commercialization of hydrogen fuel cell automobiles, and is doing its utmost to develop fusion technology

grafted with electro-mechanical technology as well as to take the initiative in the development of intelligent

smart car technology.

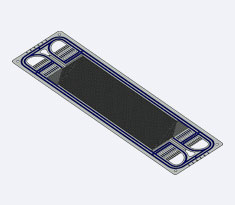

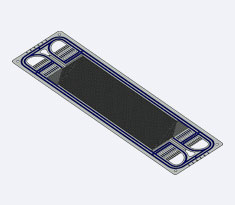

- Metal bipolar plate for fuel cell vehicles

- Metal bipolar plate is core component of the fuel cell stack along with GDL(Gas Diffusion Layer),

MEA(Membrane Electrode Assembly). Hydrogen and air, which are reaction gases, are uniformly supplied

to the active area by metal bipolar plate. Also, it functions as a current transfer and water

emissions generated by the electrochemical reaction.

Research, product development performance and success case

2015. 08 : Development of non-humidified MEA and metal bipolar plate (National R&D

project)

2018. 09 : Development of large-area metal bipolar plate (National R&D project)

- Hydrogen Sensor

- This is a sensor for detecting hydrogen leaks and evaluating the safety of the vehicle. We are the

first company in Korea which has succeeded in developing the hydrogen sensor using MEMs technology

and the first to mass produce this part.

- Pressure Sensor

- This is a sensor for monitoring the operating pressure of the hydrogen pipe and fuel cell stack

entrance/exit which leads from the hydrogen storage device. It uses fuel cell system hydrogen gas,

and because it is operated in an environment of high humidity, there are still a variety of issues

to be resolved due to freezing in cold climates. SJG SEJONG’s pressure sensor being

developed and prepared for mass production with a combined-function which is safe, overcomes

climate-related problems, and measures both pressure and temperature.

- Pressure Relief Valve–H2

- This is safety equipment which is installed in order to protect the system by reacting to pressure

which has exceeded regulations during abnormal operation of the fuel cell system while driving.

SJG SEJONG has developed a pressure relief valve for optimum performance in a humid

hydrogen environment, thereby contributing to the safety of fuel cell cars.

- Water Trap

- This is a functional component to control the condensation of vapor produced in the fuel cell

stack in order to optimize the performance and reinforce the durability of hydrogen fuel cell

vehicles. At SJG SEJONG we have developed a non-contact water level sensor which

has superior responsiveness to precise detection of the water level without coming into direct

contact with the condensate. It is a highly reliable product with optimum performance in a hydrogen

gas environment, as required in micro-engineering.

- NOx Sensor

- The nitrogen oxide sensor is attached to the exhaust after-treatment device to reduce the presence

of harmful substances in automotive exhaust gas and monitor the concentration of nitrogen oxide.

- Temperature Sensor

- The temperature sensor is installed between the oxidation catalyst of the diesel particulate

filter and the catalyst filter to quickly and accurately deliver the temperature of the exhaust gas

to the electronic control unit.

- Differential Pressure Sensor

- This device measures the difference in pressure between the entrance and exit of the diesel

particulate filter and detects the amount of collected particulate inside.

- Oxygen Sensor

- This is a sensor which measures the concentration of oxygen contained in the exhaust gas to

control the engine's air-fuel ratio in order to increase the purification rate of exhaust gas and

detect abnormalities.

- Particulate Matter Sensor

- This is a particulate matter-monitoring device which is attached to the rear of the diesel

particulate filter.

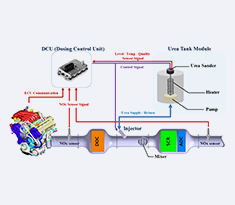

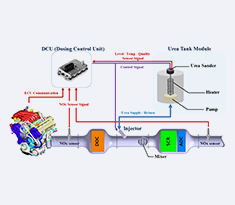

- Urea-SCR System

- This is a system necessary for satisfying emissions-related environmental regulations which uses

urea as a reductant for reducing the amount of nitrogen oxide contained in exhaust gas.

- Wheel Speed Sensor

- The wheel speed sensor is attached to the wheels of the car in order to detect changes in the line

of induction and transfer this to the system. It provides key information for the safe operation of

the vehicle and it is also related with the anti-lock braking system, the speedometer, electric

power steering system, etc.

Types of wheel sensors include the active type which uses the

hall-effect principle applied to the ABS system and the passive type which detects vehicle speed

using the electromagnetic induction principle and is applied to vehicles which are not ABS-equipped.

SJG SEJONG has also launched the Smart Type which has the added function of

detecting turning direction, and recently succeeded in developing the GMR type which can measure

tire pressure in order to connect it with the indirect tire-pressure monitoring system and mass

production of this will be undertaken in the near future. The speed sensor which has come under

recent development is connected with the parking aid system and automatic parking system in order to

further increase safety and massively improve driver convenience.

-

Hydrogen Supply and Discharge Technology for Hydrogen Fuel Cell Vehicles

Our R&D Center is ensuring the safety of fuel cell vehicles by developing a hydrogen supply system core

module to supply, recycle and discharge hydrogen gas with a suitable pressure and flow rate to the fuel cell

stack, which contributes to performance optimized to all environments. SJG CENTRAL R&D CENTER is accelerating

continuous development of new technologies.

We are focusing not only on reinforcing durability, but also on ensuring low temperature ignition and

perfecting hydrogen emissions reduction technology to remove the hazard of surplus gas in preparation for

mass commercialization of future eco-friendly vehicles.

-

High Precision Sensor Chip Design Technology which Combines MEMs process

By securing thin-film design technology combining micro electromechanical system process technology, we have

improved low-power consumption and reaction speed which are the core performance components of the sensor.

The high-precision sensor chip design technology is an advanced technology which makes it possible to

establish foundation of mass production, increasing product price competitiveness and improving

productivity.

SJG SEJONG will not hesitate to actively invest in and supporting

research and development for the procurement of advanced technology in the domestic sensor market which

currently relies on imports.

-

Exhaust After-treatment to reduce Nitrogen Oxide

We are doing everything we can at SJG SEJONG to secure technology to reduce nitrogen oxide

in exhaust gas in accordance with the globally tightening regulations on emissions (Euro-6, NOx).

The urea-SCR system which injects urea (aqueous ammonia) into the exhaust system via the dosing control

unit, purifies harmful gas contained in the exhaust gas by using a redox reaction of nitrogen oxide. We are

endeavoring to promote technological development for full-scale commercialization by introducing advanced

technology to ensure improved performance and reliability of the urea-SCR system to secure our own

technology.

-

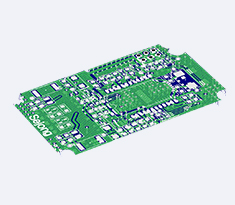

Technology for Electromagnetic Wave Resistance Circuit Design

As semiconductor chip technology becomes miniaturized and obtains high-speed and low-power capability, the

electromagnetic resistance of electronic devices may become lowered. Since sensors and control devices, etc.

are particularly connected with the safety of the driver, there is a need for design technology which can be

applied to external electromagnetic disturbance as well.

SJG SEJONG is preventing system malfunction caused by external electromagnetic disturbance

and possesses unrivaled design device/circuit/software design technology which doesn't damage performance or

hinder external leakage radiation of high-frequency power. We combine high-frequency external interference

waves with electromagnetic waves to prevent adverse effects on the system through noise filtering and PCB

design technology.

-

Manufacturing technology of metal bipolar plate

SJG EV has flow field forming technology for each thin plate metal material. In addition, SJG EV has

gasket technology for airtightness and coating technology for improving bipolar plate performance for

corrosion / durability / conductivity.

Also, SJG EV built manufacturing technologies such as assembling, inspection and evaluation, and are

producing metal bipolar plate on a large scale. Finally, SJG EV is developing technology in various fuel

cell fields by investing actively and supporting commercialization.

본 웹사이트에 게시된 이메일주소가 전자우편 수집 프로그램이나

본 웹사이트에 게시된 이메일주소가 전자우편 수집 프로그램이나  본 웹사이트에 게시된 이메일주소가 전자우편 수집 프로그램이나

본 웹사이트에 게시된 이메일주소가 전자우편 수집 프로그램이나